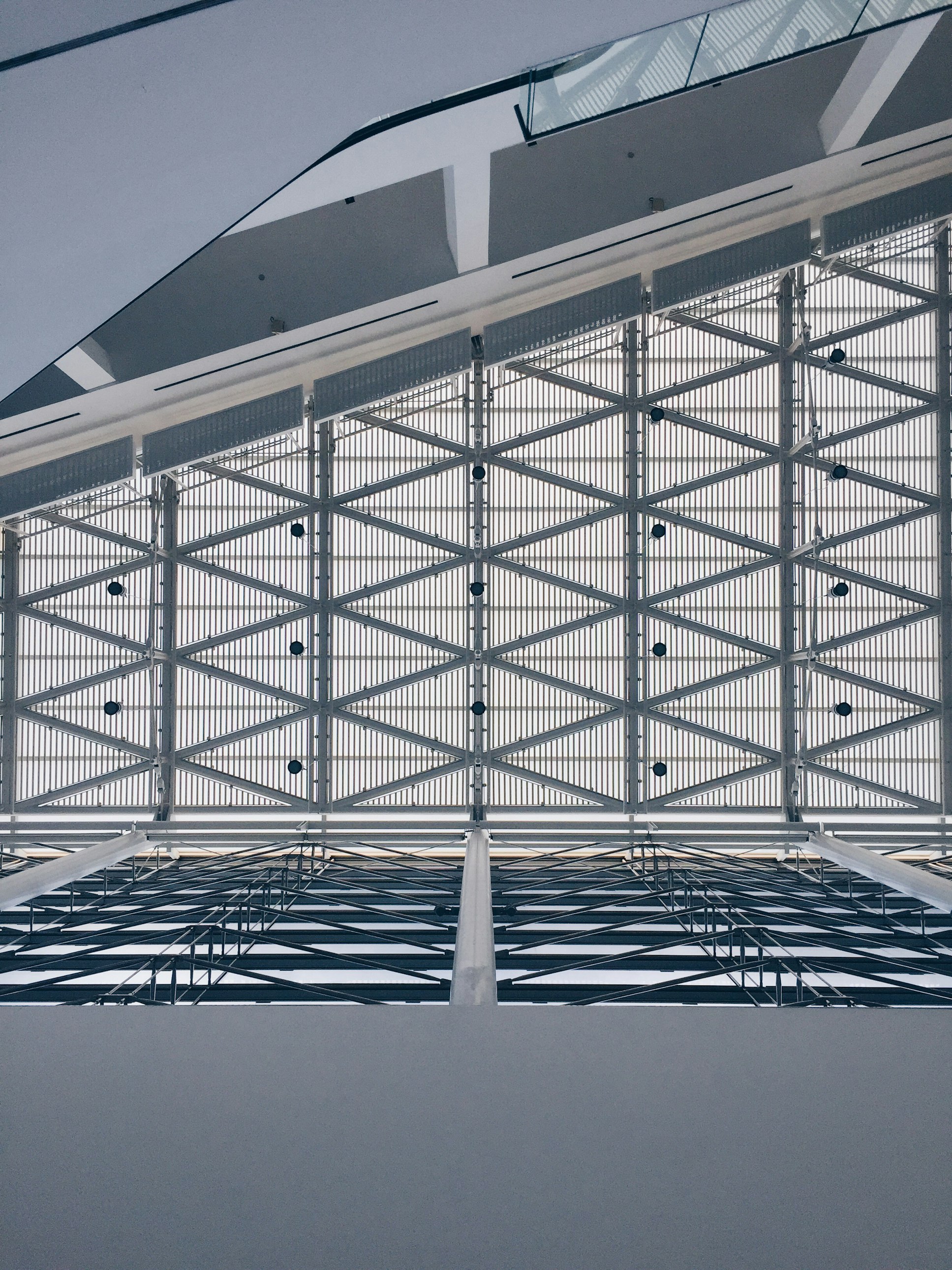

Perforated metal, characterized by its pattern of holes, slots, or decorative shapes, has become a significant material in the design and construction of commercial buildings. Its choice is often underpinned by its functional and aesthetic qualities, offering designers versatility when considering lighting, ventilation, and acoustic management. The material is prized for its strength-to-weight ratio, providing a durable yet lightweight solution for a variety of applications such as facades, screening, and interior design features.

However, the use of perforated metal in commercial construction also presents certain challenges. While it offers distinct visual and practical benefits, considerations regarding cost, manufacturing complexity, and maintenance requirements must be addressed. The lifecycle and environmental impact of metal production, as well as its performance under varying climate conditions, are important factors that influence the decision-making process among architects and builders.

By evaluating the advantages against the potential drawbacks, stakeholders can determine the suitability of perforated sheet metal for their specific commercial projects. Factors such as location, building function, budget constraints, and design objectives play a critical role in the material selection process, impacting the overall success and longevity of a commercial building’s design.

Advantages of Perforated Metal

Perforated metal provides commercial buildings with distinctive benefits ranging from aesthetic enhancement to functional gains in ventilation, acoustics, and lighting.

Enhanced Aesthetics

Perforated metal offers varied patterns and materials that can be tailored to the visual requirements of any design. Distinct patterns and customizability add to the structure’s uniqueness, creating striking facades or intricate interior details.

Improved Ventilation

Using perforated metal allows for increased airflow. A building’s need for mechanical ventilation can decrease, as perforated designs facilitate natural air passage, which is both cost-effective and energy-efficient.

Effective Sound Absorption

The perforations in the metal disrupt sound waves, reducing noise levels in an area. This absorption is particularly beneficial in busy commercial environments, helping to create a more conducive workspace or public area.

Natural Lighting Benefits

Perforated metal permits the entry of natural light while mitigating glare and heat. Optimal use of daylight not only reduces reliance on artificial lighting but also enhances the comfort of interior spaces.

Disadvantages of Perforated Metal

Perforated metal, while versatile and functional, presents certain challenges in commercial building applications. These include increased cost, structural limitations, and maintenance considerations.

Cost Considerations

Perforated metal can be more expensive than solid materials due to the additional processing required to create the perforations. Metal sheets are typically priced by weight and the perforation process involves the removal of material, which may increase waste. Economically, this can affect the overall budget for a construction project.

- Additional processing: Higher costs due its manufacturing.

- Material waste: Potentially less material efficiency.

Structural Limitations

The integrity of metal can be compromised through perforation, leading to reduced load-bearing capacities. In commercial buildings, where structural integrity is paramount, this can restrict the use of perforated metal to less structural or non-load-bearing applications. Detailed engineering is required to ensure that the material meets safety standards.

- Reduced strength: Weaker than non-perforated counterparts.

- Engineering needs: Requires rigorous assessment for safety.

Maintenance Challenges

Perforated metal requires regular maintenance to retain its appearance and avoid damage from environmental factors such as corrosion. Small openings in the metal can trap dirt and moisture, necessitating frequent cleaning. Moreover, it may be more challenging to repair perforated metal compared to solid materials due to its unique structure.

- Cleaning: Difficulty due to trapped dirt and moisture.

- Repair: Complexities in restoring damaged areas.

Practical Applications in Commercial Buildings

The integration of perforated metal in commercial building designs serves both functional and aesthetic goals. This section outlines its specific applications across three core aspects of commercial architecture.

Architectural Facades

Perforated metal panels are predominantly utilized for building exteriors, where they contribute to both visual appeal and energy efficiency. They allow natural light to filter through, reducing the need for artificial lighting, while also providing shade to reduce cooling costs. The ability to customize patterns lets architects create unique branding elements for the facade.

Interior Design Elements

In commercial interiors, perforated metal is frequently employed for its versatility and modern aesthetic. Used in:

- Ceiling tiles: Enhances acoustics and hides utility infrastructure.

- Room dividers: Provides an open feel while sectioning off spaces.

- Decorative panels: Adds textural interest to walls or furniture.

Safety and Privacy Features

Perforated metal from perforated metal manufacturers serves key roles in safety and privacy within commercial buildings. Its applications include:

- Balustrades and stair guards: Ensures safety while maintaining visibility.

- Window screens: Offers privacy without sacrificing natural light.

- Security fencing: Secures the perimeter of a property while maintaining an inviting exterior.